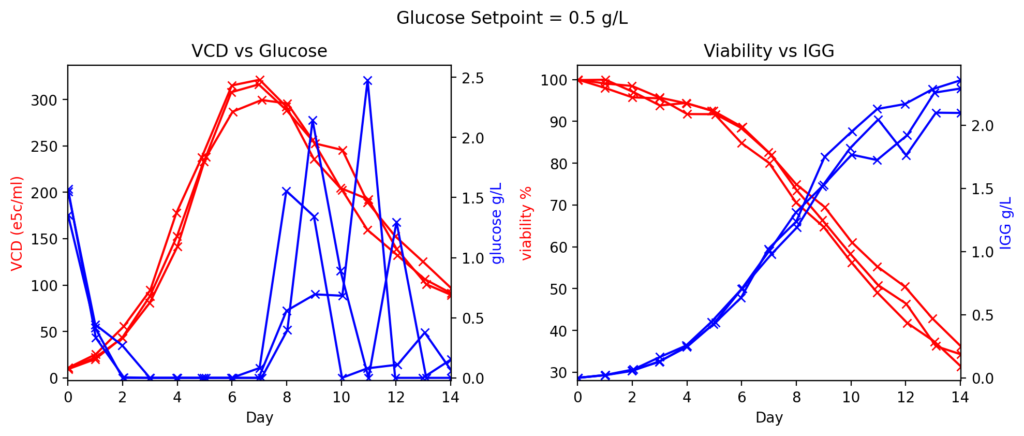

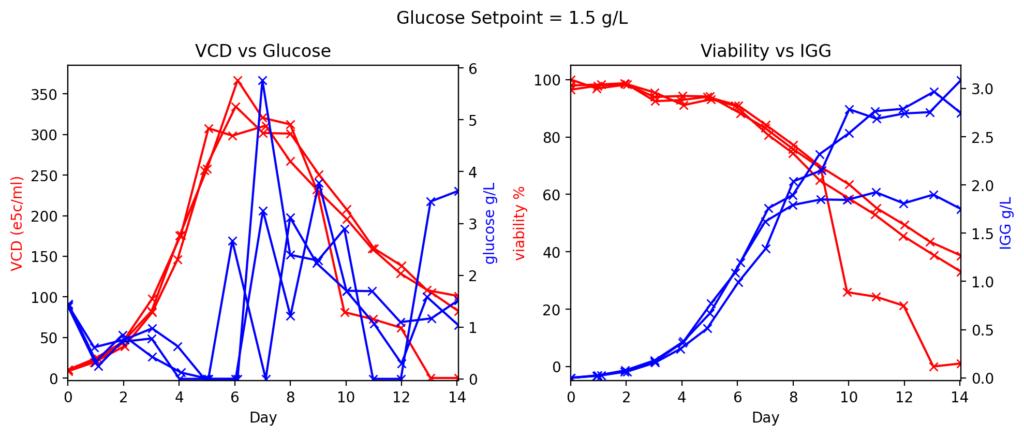

Imagine this: you’ve read some literature that recommends keeping glucose levels low in your cell culture, so you develop a new feeding strategy. You completely remove glucose from the concentrated feed and move it to its own glucose feed so you can control the level. But, without being sure how accurate your glucose consumption predictions are or what the affect of running out of glucose will be, you have to try a few setpoints and run the experiments:

It seems that not only was 0.5 g/L too low (impacting VCD and titer), but your glucose consumption rate prediction isn’t doing a good job, undershooting during exponential growth and overshooting once stationary phase arrives.

What if you could have just simulated the process and found this out without running any experiments at all? We know enough about how bioreactors work to a reasonable degree of accurately model what will happen without actually running the experiment. While we would still need to run experiments for individual cell lines, platform design choices could be readily informed without running any experiments. We could be spending all of our time investigating the exact characteristics of a specific cell line rather than troubleshooting a bioreactor setup.

Introducing CellCulture-Simulator (CC-Sim), a tool capable of simulating an upstream process. Given a bioreactor setup, media definition, control strategies, assays, and actuation devices, CC-Sim can simulate a process and display metrics for whatever happened. Anything from screening of process changes to developing new data science techniques in the cell culture process could be aided with this simulation.

The above plots were generated from a simulated cell culture process using CC-Sim.

Table of Contents

- Abstract

- Features

- Technical Description

- History

- Use Cases

- Example Runs

- Fed Batch

- Perfusion – WIP

- Roadmap and Future Updates

- Appendix

CC-Sim is available free with a source-available non-commercial license, so feel free to play around with it (or even contribute) in your own time. You can access the source code here; further questions are welcome by email or my contact form.